We facilitate all steps of sourcing supply in china

Importing from China can be a high-risk, time-consuming procedure. Identifying the right source and supply chain in China can be challenging when having to deal with legalities, local practices, and all kinds of bureaucracy and cultural barriers.

Phoenix is specialized in international trade with China, including sourcing and managing the production of goods in China for export to the rest of the world. We work closely with our clients to facilitate all steps of the sourcing supply chain in China including production, delivery, clearance, and shipping.

We invite you to know our services

products & suppliers Research

We are experienced in searching and locating a range of manufacturers and distributors related to your product. We issue a quotation within 5 working days depending on your projected purchase quantity, specifications, and delivery terms.

Factory Verification

It is imperative to check the source before making any purchase. Our service includes verifying factory and supplier credentials in order to ensure a smooth production process and delivery schedule according to all agreed terms.

Off-site Audit

We carry out preliminary audits to verify factory credentials. We do so by conducting an online background check by accessing public records regarding registrations, licens/es, official bank account, legal representative, registered capital, scope of business, official address, website, and others. We also check by telephone to confirm their physical location.

On-site Audit

An inspection verifies all aspects of operation from production capacity, to personnel and working conditions to ensure compliance with international standards in accordance with ISO 9000 and SA 8000. This ensures supplier suitability in order to avoid fraud and the delivery of faulty goods.

Interpreter Service

We offer translation and interpretation services for factory visits, attending exhibitions, supplier meetings, and other important events according to clients’ needs and schedules.

Purchasing agent

As purchasing agent, Phoenix acts on behalf of its clients to support all purchasing activities designated by the client including identifying and comparing suppliers, quality tests, due diligence, production capacity analysis, product specifications and cost analysis.

Organization and Search Process

- Search for products / suppliers.

- Validation of records, quality certifications, production capacity, product line among others.

- Negotiation of minimum quantities of purchases (MOQ).

- Own Brand Development (OEM) (if applicable).

- Shipment of samples for quality verification by the buyer.

- Initial price negotiation.

- Final choice of provider.

- Factory visit.

- Sales agreement, signature of purchase contract.

- Payment.

- Production monitoring.

- Documents preparation.

- Advice on the best logistic and transportation.

- Factory visit to verify the final product.

- Container Load.

Own Brand Development (OEM)

Phoenix supports clients’ operations through own brand development. Our marketing and branding team creates branding solutions including logo and brand identity, packaging and label design, and all other related marketing materials.

Freight Management

Through our partners’ logistics network, we identify the best solution in terms of value, logistics, and lead time. We undertake all the necessary transport planning and operations to meet our clients’ schedule and budget. We present our clients with a range of options for them to select the most suitable one.

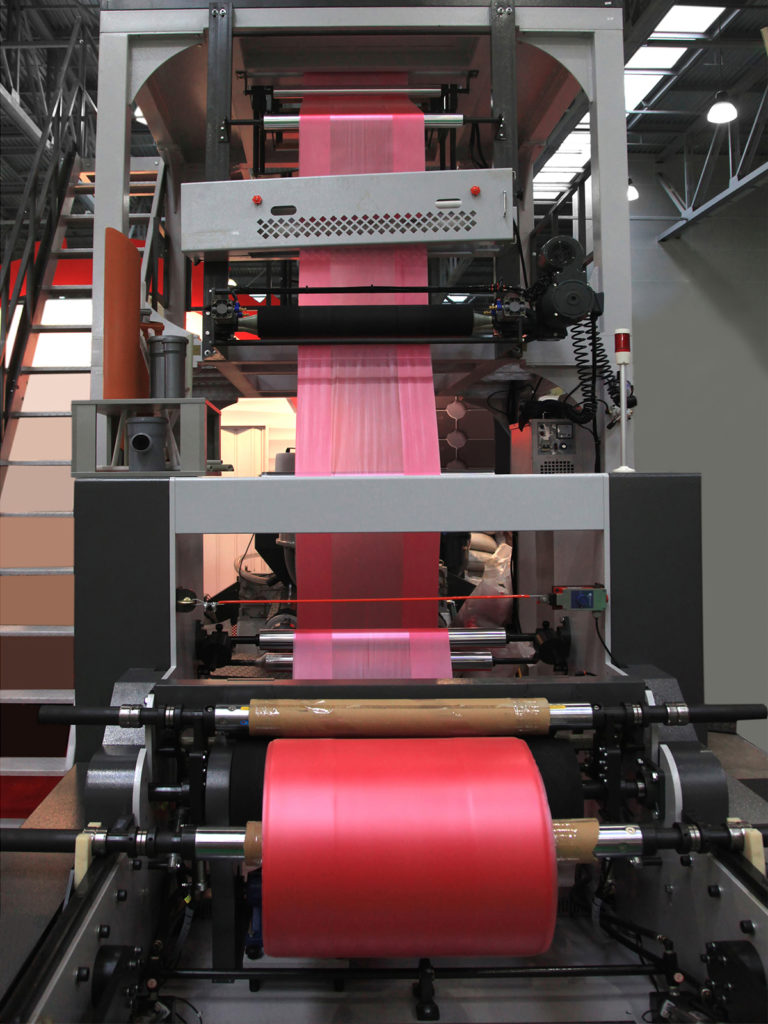

Product Inspection & container load

Product inspection protects against costs and damages arising from defective products, improper packaging, missing documentation and certificates, and discrepancies from agreed standards in production at the time of loading.

- Initial Product Inspection

We carry out an initial product inspection to make sure the supplier abides by the agreed terms and specifications. Furthermore, we do a check to ensure suppliers’ manufacturing equipment, facilities, and raw materials conform to the needs of production as stipulated in the contractual agreement.

- Production Inspection

We carry out standard product inspection when the order is between 20% and 80% of the manufacturing process. We check for measurements, weight, packaging, labeling, and other parameters.

- Pre-Shipment Inspection

We carry out pre-shipment inspection in order to confirm production conformity. We also check for specifications conformity during production, shipment and at the port of loading.

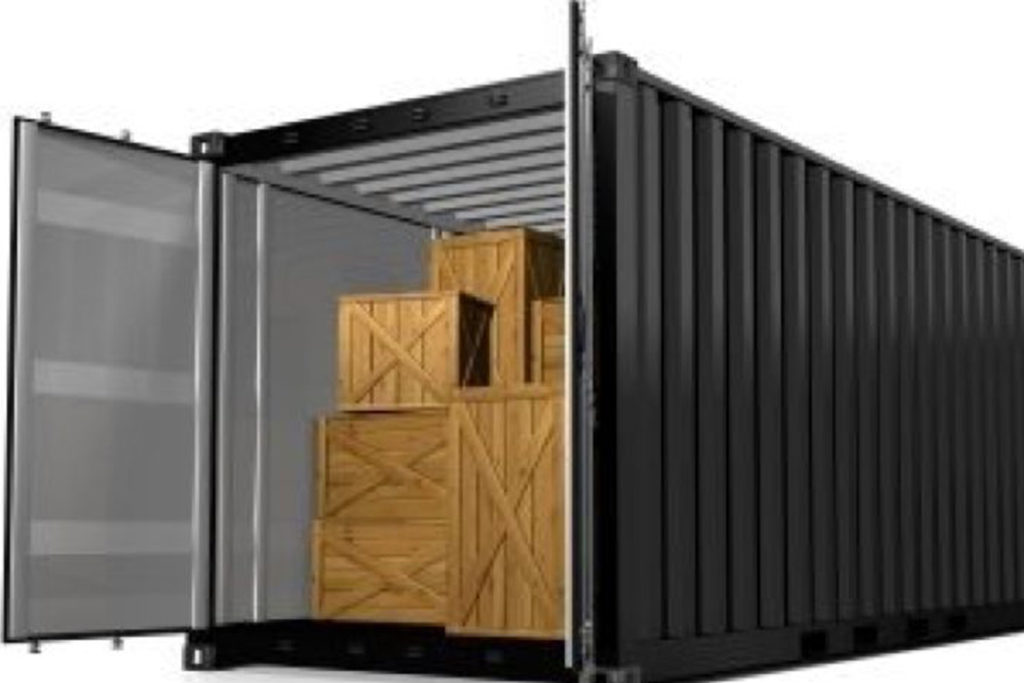

- Container load

We carry out quantity, packing list, and container checks. We monitor loading to ensure packaging is not mishandled. We also check for the correct designated marking on the boxes.

We offer charts and data of the inspection results prior to shipments along with all relevant supporting information including photos and video files to ensure quality and other specifications are met.

After Sales Support

We are committed to the highest standards of after sales support. To this extent, we maintain close contact to verify our clients’ satisfaction and strive to swiftly look into and correct any discrepancies that may have occurred.

Business Trips and Onsite Visits

Doing business with China presents a unique set of challenges with many barriers to overcome. Should you choose to travel to China, Phoenix offers a service package including airport reception and pick-up, an assistant –translator, guided visits to factories and meeting with suppliers, day and night tour around the city, support during the entire stay and any other arrangements needed to make your business trip a successful one.